What is cloud migration in manufacturing plants?

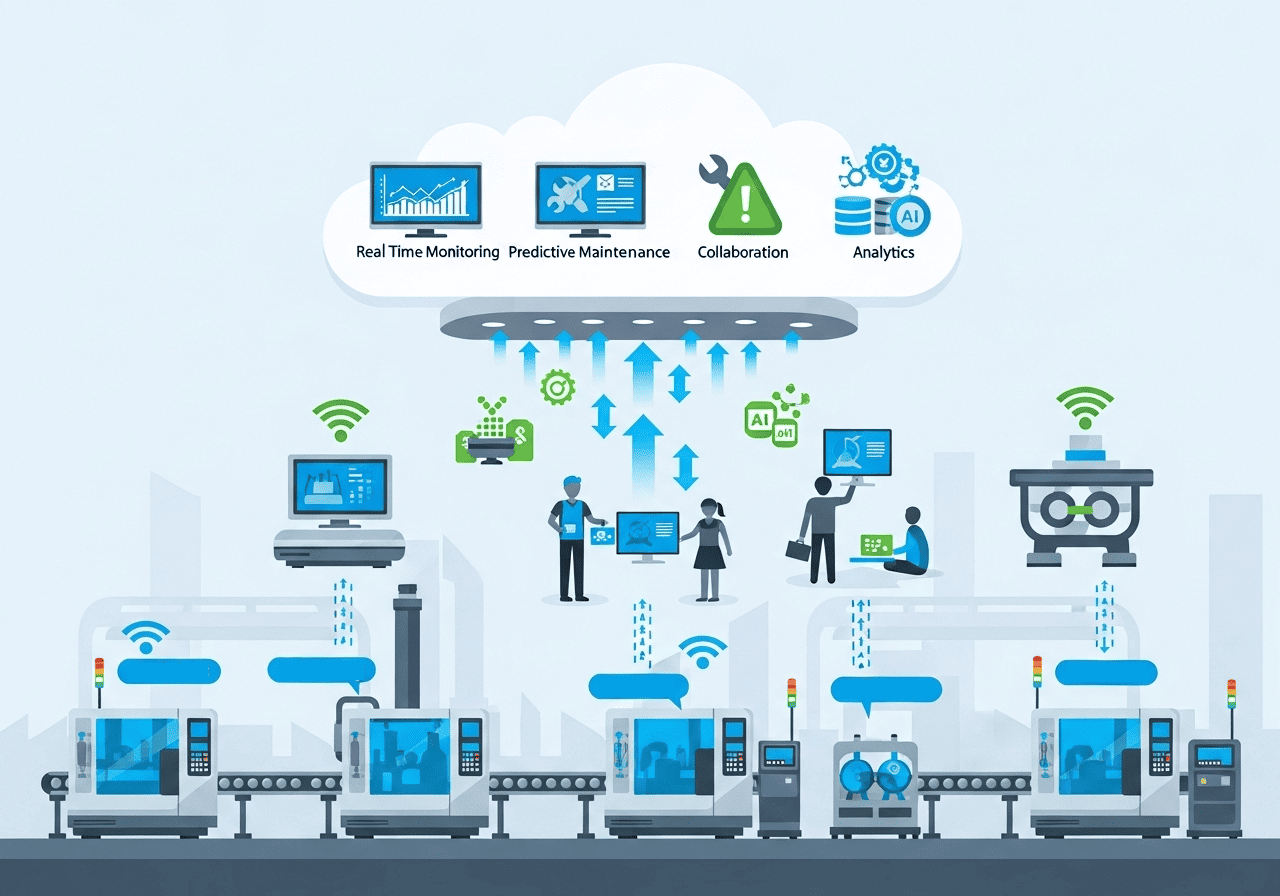

Cloud migration in manufacturing plants involves moving production-related applications, data, and infrastructure to cloud environments. This transition enables real-time monitoring, automation, and scalable resource allocation. Manufacturers can optimize operations, reduce downtime, and improve collaboration across departments. By adopting cloud technology, plants gain centralized control of systems, streamlined data access, and improved analytics capabilities, resulting in enhanced efficiency, flexibility, and the ability to respond quickly to production demands and market changes.

Why is cloud migration important for production efficiency?

Cloud migration is important for production efficiency because it enables real-time data access, automated workflows, and centralized control of manufacturing operations. By moving systems to the cloud, plants can quickly adjust resources, monitor machinery performance, and track inventory levels. Cloud platforms allow seamless integration of production data, predictive analytics, and resource optimization. This leads to reduced downtime, better decision-making, and streamlined operations, helping manufacturing plants increase output, reduce waste, and maintain high-quality production standards.

What cloud migration strategies are suitable for manufacturing plants?

Cloud migration strategies suitable for manufacturing plants include rehosting, refactoring, replatforming, and hybrid deployment models. Rehosting moves existing applications directly to the cloud, while refactoring optimizes applications for cloud performance. Replatforming involves minimal changes to leverage cloud capabilities, and hybrid deployment allows a mix of on-premise and cloud solutions. Consultants help select strategies based on production requirements, system complexity, and scalability needs, ensuring an efficient, secure, and low-risk transition to cloud-based manufacturing operations.

How does cloud migration improve real-time monitoring?

Cloud migration improves real-time monitoring by centralizing production data and providing access to live operational metrics from anywhere. Sensors, machinery, and production systems can send data to cloud platforms for continuous analysis. Manufacturers can track equipment performance, detect anomalies, and implement predictive maintenance to prevent downtime. Real-time dashboards allow managers to make informed decisions, optimize workflows, and enhance productivity. This ensures production efficiency, reduces operational delays, and supports continuous improvement in manufacturing processes.

How can cloud migration reduce production downtime?

Cloud migration reduces production downtime by enabling predictive maintenance, automated alerts, and centralized monitoring. Data from machines and sensors is continuously analyzed to identify potential failures before they occur. Cloud-based analytics helps schedule maintenance during non-peak hours, preventing unexpected stoppages. Additionally, cloud platforms allow quick deployment of software updates and process adjustments without interrupting operations. This proactive approach ensures smooth production, minimizes delays, and improves overall efficiency in manufacturing plants.

How does cloud migration optimize resource utilization?

Cloud migration optimizes resource utilization by providing scalable computing, storage, and processing capabilities. Production data, inventory levels, and energy consumption can be monitored and analyzed in real time. Cloud systems allow dynamic allocation of resources to match production demands, reduce waste, and enhance operational efficiency. Automated workflows and analytics help manufacturers plan production schedules, manage workforce deployment, and improve machine usage. Optimized resource utilization reduces costs, increases throughput, and supports sustainable manufacturing operations.

What role does data analytics play in cloud-based manufacturing?

Data analytics plays a critical role in cloud-based manufacturing by turning raw production data into actionable insights. Cloud platforms collect data from machines, sensors, and production lines, which is analyzed to identify inefficiencies, optimize schedules, and predict maintenance needs. Analytics helps manufacturers monitor performance trends, improve quality control, and make informed operational decisions. By leveraging data insights, plants can enhance production efficiency, reduce waste, and implement continuous improvement initiatives for better overall performance.

How can cloud migration improve collaboration across departments?

Cloud migration improves collaboration by centralizing production data and making it accessible to multiple departments in real time. Operations, maintenance, supply chain, and management teams can share insights and coordinate actions efficiently. Cloud-based communication tools, dashboards, and workflow systems facilitate transparency and quicker decision-making. By enabling seamless collaboration, plants can reduce delays, align production goals with business objectives, and respond rapidly to issues, ultimately improving productivity, efficiency, and overall manufacturing performance.

How does cloud migration enhance production scalability?

Cloud migration enhances production scalability by providing flexible infrastructure that can handle increasing workloads and production demands. Cloud platforms allow manufacturers to expand storage, computing power, and network capacity on demand. New production lines or additional machinery can be integrated into the cloud system quickly. This flexibility ensures that plants can scale operations efficiently without major capital investments or downtime, enabling them to meet growing demand, adapt to market changes, and maintain high levels of productivity.

What security measures are important during cloud migration?

Security measures are crucial during cloud migration to protect sensitive production data and intellectual property. Manufacturers should implement encryption, access controls, firewalls, and continuous monitoring. Regular audits and risk assessments ensure compliance with industry standards. Data backup and disaster recovery plans minimize the impact of potential breaches. By enforcing strict security protocols, manufacturing plants can prevent unauthorized access, safeguard operational information, and maintain trust while improving efficiency through cloud-based systems.

How does cloud migration support predictive maintenance?

Cloud migration supports predictive maintenance by enabling continuous monitoring of machinery and equipment through cloud-based sensors and analytics. Data is analyzed to identify patterns that indicate potential failures, allowing maintenance to be scheduled proactively. This reduces unexpected breakdowns, extends equipment lifespan, and minimizes downtime. Cloud platforms provide dashboards and alerts to guide maintenance teams efficiently. Predictive maintenance improves operational efficiency, reduces costs, and ensures that production lines run smoothly without interruptions.

How can cloud migration reduce operational costs in manufacturing?

Cloud migration reduces operational costs by eliminating the need for on-premise hardware, optimizing resource usage, and automating workflows. Centralized data management and analytics reduce waste, prevent overproduction, and improve energy efficiency. Maintenance scheduling and predictive insights prevent costly downtime. Cloud platforms allow manufacturers to scale resources according to demand, avoiding overinvestment. These cost-saving measures improve production efficiency while enabling manufacturers to invest in innovation and maintain competitiveness in the industry.

How does cloud migration enable real-time inventory management?

Cloud migration enables real-time inventory management by centralizing data from production lines, warehouses, and suppliers. Sensors and tracking systems send updates to the cloud, allowing manufacturers to monitor stock levels, track raw materials, and anticipate shortages. Automated alerts and reporting tools help optimize ordering and reduce overstock or waste. Real-time visibility improves production planning, reduces operational delays, and ensures that materials are available when needed, enhancing efficiency and supporting continuous manufacturing operations.

What role does automation play in cloud-based manufacturing?

Automation plays a critical role in cloud-based manufacturing by streamlining repetitive tasks, monitoring production processes, and managing workflows. Cloud platforms integrate automated controls, scheduling, and reporting tools that reduce human errors and improve accuracy. By automating data collection, analysis, and routine operations, manufacturers can optimize machine utilization, increase throughput, and enhance efficiency. Automation in the cloud supports predictive maintenance, quality control, and real-time decision-making, leading to improved production performance and operational excellence.

How do manufacturers measure production efficiency after cloud migration?

Manufacturers measure production efficiency after cloud migration by tracking key performance indicators (KPIs) such as equipment utilization, cycle times, output rates, and downtime. Cloud platforms provide dashboards and analytics tools to visualize trends and identify bottlenecks. Real-time monitoring allows continuous assessment of workflows, energy usage, and resource allocation. By analyzing these metrics, manufacturers can optimize operations, implement improvements, and ensure that cloud migration delivers tangible gains in efficiency, productivity, and overall production performance.